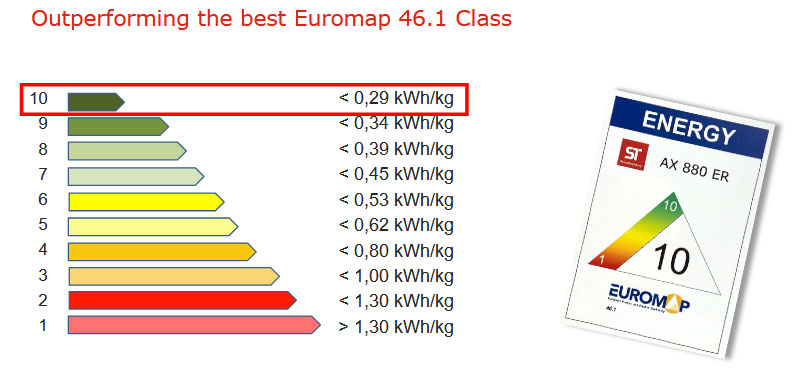

Green Performing best practices

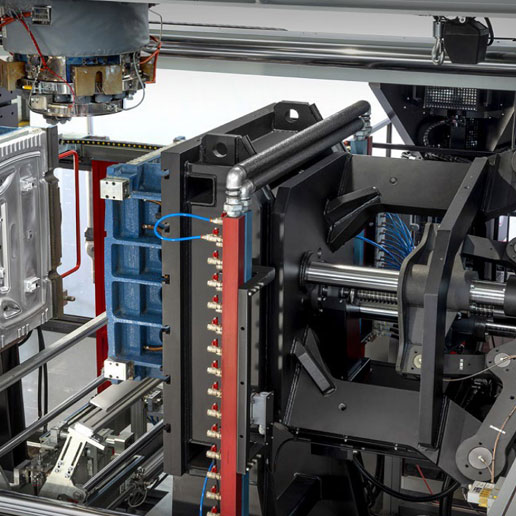

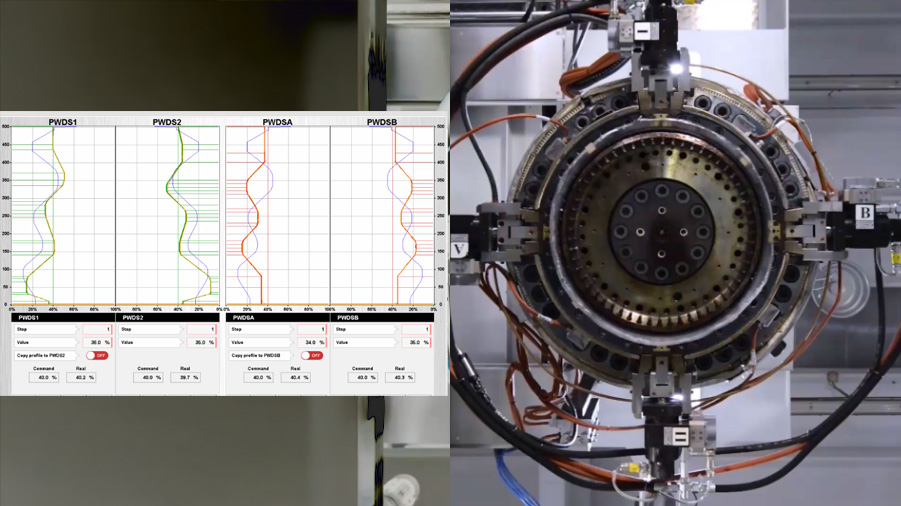

We design machines that minimize energy consumption, reduce waste and optimize material usage

Our solutions help manufacturers achieve their environmental goals while maintaining superior production efficiency and quality standards.