Top quality standards

STONE is a unique Company able to design, manufacture and start up top green-performing machines qualified by 25 years of experience of Asian team and by the whole ST Group technical department competence.

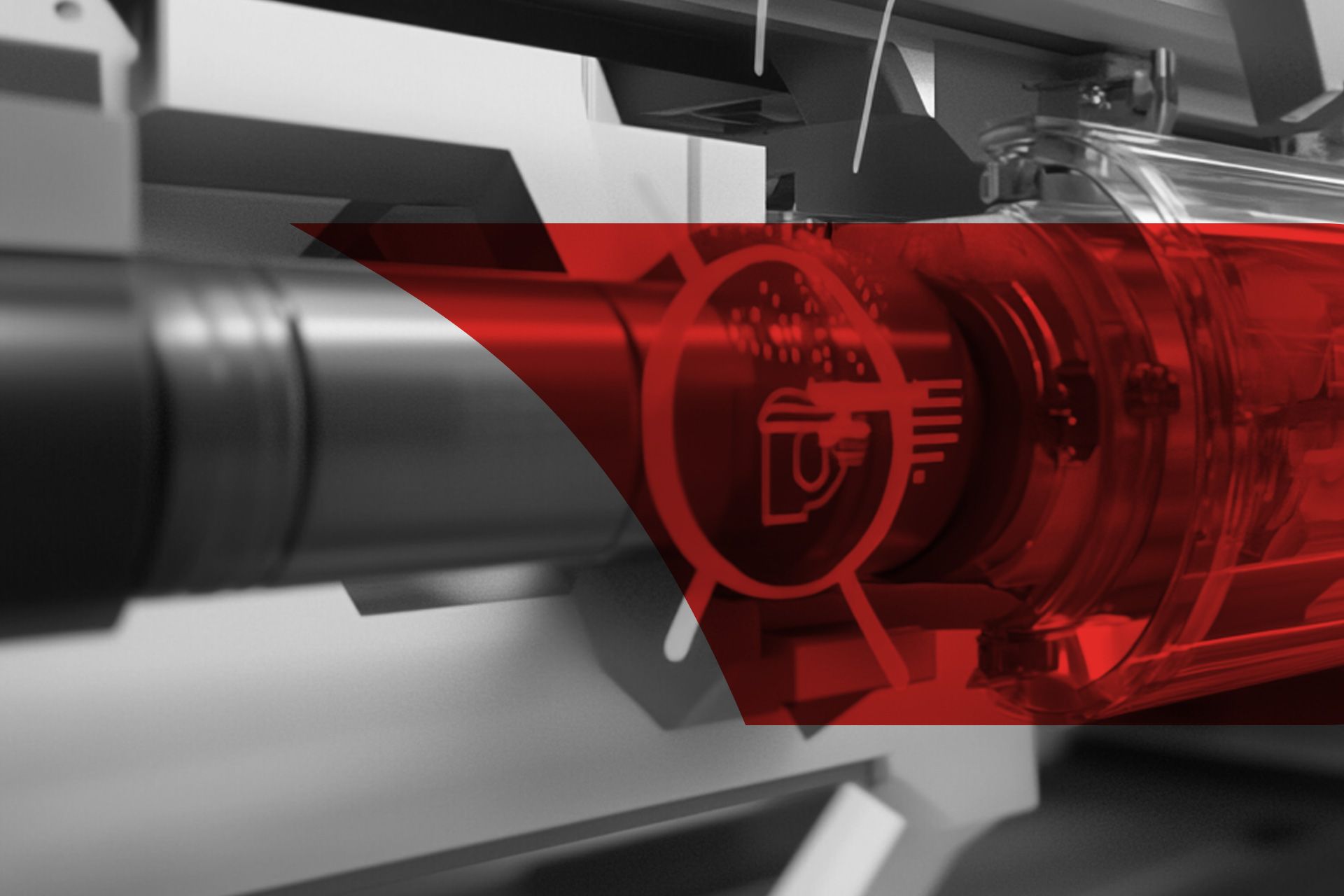

Extrusion section

Special screw/barrel design allowing:

- intensive usage of recyclates granting a minimum energy consumption and best performances in output

- exceptional process stability

- high maximum througoutput capacities

- excellent melt homogeneity

- top energy efficiency in running HDPE, HMWPE or PA or barrier materials

- homogeneous material and better colour mix (thanks to the extruder with long screw lengths in combination with improved mixing zones)